Oil and Gas Equipment Manufacturer Supply Integration

A global corporation, manufacturing equipment and components. Their products are used in oil and gas drilling and production operations, oilfield services, and supply chain integration to the upstream oil and gas industry.

Download Oil and Gas Equipment Manufacturer Supply Integration

Challenge:

The customer sought ways to optimize MRO efficiencies and manage indirect spend so they could get better control of their procurement processes and inventory. In addition, they sought to clean up their data and increase the visibility and control of their indirect spending budget.

Solution:

Implement our Automated Supply Program (ASP)—an advanced, indirect material supply chain software used for industrial supply integration, in addition to our proven processes to control MRO indirect spending.

Key Result:

Reduced total cost of ownership by 24.2% in the first year post-integration.

Product Advantages:

- Robust product database creation

- Reliable, strategic procurement automation

- Optimized supply chain for continuity of service

- Experienced, creative sourcing by professionally certified buyers

Background:

The customer was challenged with finding a way to better manage their MRO indirect spending so they could get better control of their procurement processes, control their inventory, clean up their data, as well as have visibility and control of their indirect spending budget.

After conducting an extensive search, they approached us to help create savings and efficiencies. Before our involvement, the customer had no integrated supplier presence. Our team implemented our Automated Supply Program (ASP)—an advanced, indirect material supply chain software—and our proven processes to solve the various challenges the customer faced.

Requisitions

Challenge:

All tooling requisitions were filtered through the customer’s buyers using paper forms. Then, the information on these forms was entered into the Enterprise Resource Planning (ERP) system by hand. This means the Buyer would have to route the forms physically to different managers for approval before placing the order. As a result, the process of obtaining approvals led to extended cycle times, sometimes taking several business days from form generation to order placement.

Solution:

We introduced our ASP system to automate requisition entry and also to obtain manager approvals electronically. ASP allows the requestor, the buyer, and all approvers to see the flow of the order in real-time. Now, managers can both approve and reject orders from their phones and computers. ASP also saves and organizes past requisitions in a searchable database for greater transparency. By eliminating paper requisitions, we significantly improved cycle times and visibility of spend. Furthermore, ASP reduces inventory as a result of eliminating the float required in the procurement-to-payment process.

Invoices

Challenge:

Because there was no integrated supplier, the accounting department had to reconcile hundreds of different supplier invoices manually each month.

Solution:

ASP now sends the accounting department a weekly consolidated product invoice for all production and capital expenditures. We customized the system’s tracking fields to match their system fields back to the manufacturing production cell, cost center, and job, significantly reducing invoice reconciliation times.

Example:

PRE-INTEGRATION 900 invoices/month at $35 per invoice $31,500 per month

POST-INTEGRATION 4 invoices/month at $100 per invoice $400 per month

Dispensing Machines

Challenge:

The customer had dispensing machines from two different suppliers. Each one used a different software system and had no customer interface for tracking and reporting daily expenses. As a result, the data transfer incompatibility and lack of reporting prevented the customer from gaining insight into the machines’ usage. Because of this, they could not implement procedures to support usage rates.

Solution:

In order to manage and reduce MRO indirect spend, we installed our dispensing machines, all of which feed into our ASP software. Then we set up automated daily transaction reports for production managers to see daily spending details for individual production work cells. The daily usage reports and open order reports are sent automatically to the customer’s accounting team in order to help manage current budget states. This also helps them make informed decisions and forecast spending. Furthermore, ASP sends reports to Ferguson Industrial for review—enabling our associates to make recommendations for usage control that will improve the customer’s spend.

Buying and Sourcing

Challenge:

Multiple buyers were involved in sourcing cell production purchases and spot-buying spare parts for maintenance.

Solution:

Our new systems and processes consolidated procurement into a process easily managed by one buyer. As a result, this provides more efficiency, reduces cycle time, and enhances inventory management. Together, this contributes to a lower total cost of ownership.

Additional Results

- Total cost of ownership savings of more than 24.2%

- A total cost savings of 12.6% with a 6.1% product benchmark savings for the first year

- 100% visibility of all maintenance inventory in ASP

- Added 10 dispensing machines for a total of 22, all fully utilized with product required at the cell, reducing storeroom traffic and increasing storage efficiency

- Inventory cleansed, cataloged and cycle-counted to comply with Generally Accepted Accounting Principles (GAAP)

- Warranty management program managed and supported by Ferguson

- Elimination of p-cards

- Items added to ASP with full visibility of product detail, identification of repetitive spend items and reduction of multiple item codes for the same material within the system

- Implemented budget controls to restrict usage and quantity, which were applied to user profiles for select items within the dispensing machines and storeroom

- Robust ASP reporting and KPI program with standard customer dashboards and access to multiple reports for spend, budget controls by cell, inventory visibility, etc.

- Improved inventory by consolidating redundant part numbers (including redundant part numbers by multiple manufacturers), eliminating multiple manufacturers that had not been formally approved for the manufacturing process and improving visibility to customer personnel of available product

- Improved reliability and control of the supply chain, the right approved product and the right amount of on-hand inventory

View Similiar Case Studies

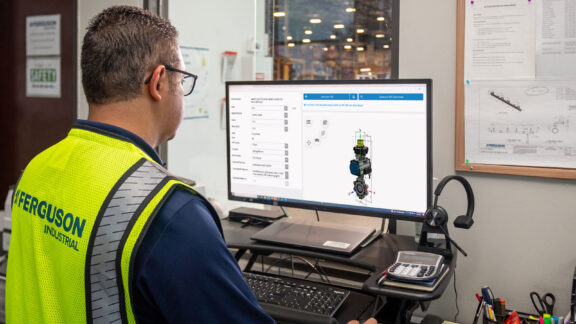

Our associates identified an opportunity to use our online Automated Valve Configuration Tool to build out exactly what the customer needed. In less than 15 minutes, our flow control experts were able to walk the customer through the process of configuring an FNW® automated ball valve package.

Expert technical assessment, material selection, and supply of Polypropylene at a quartz processing facility in North Carolina.

Providing a North Carolina quartz processing plant with contaminant-free air with a lifecycle many times greater than steel pipe—ultimately saving the plant thousands in maintenance, repair, and replacement costs.