Providing Products and Technical Support for Clemens Food Group

As design-build experts, we offer competitive pricing and timely delivery of material to meet deadlines.

PRODUCTS USED

- Valves

– FNW™

– Apollo Valves

– Milwaukee Valve

– Flow-Tek - Victaulic Pressfit®

- Victaulic grooved

- Actuation

- Stainless steel pipe

- Stainless steel weld fittings and flanges

- Stainless steel SP114 fittings

- Stainless steel 3000# fittings

- Carbon steel pipe and fittings

- FBE pipe

- MDPE pipe

- Gauges

- Forged steel fittings

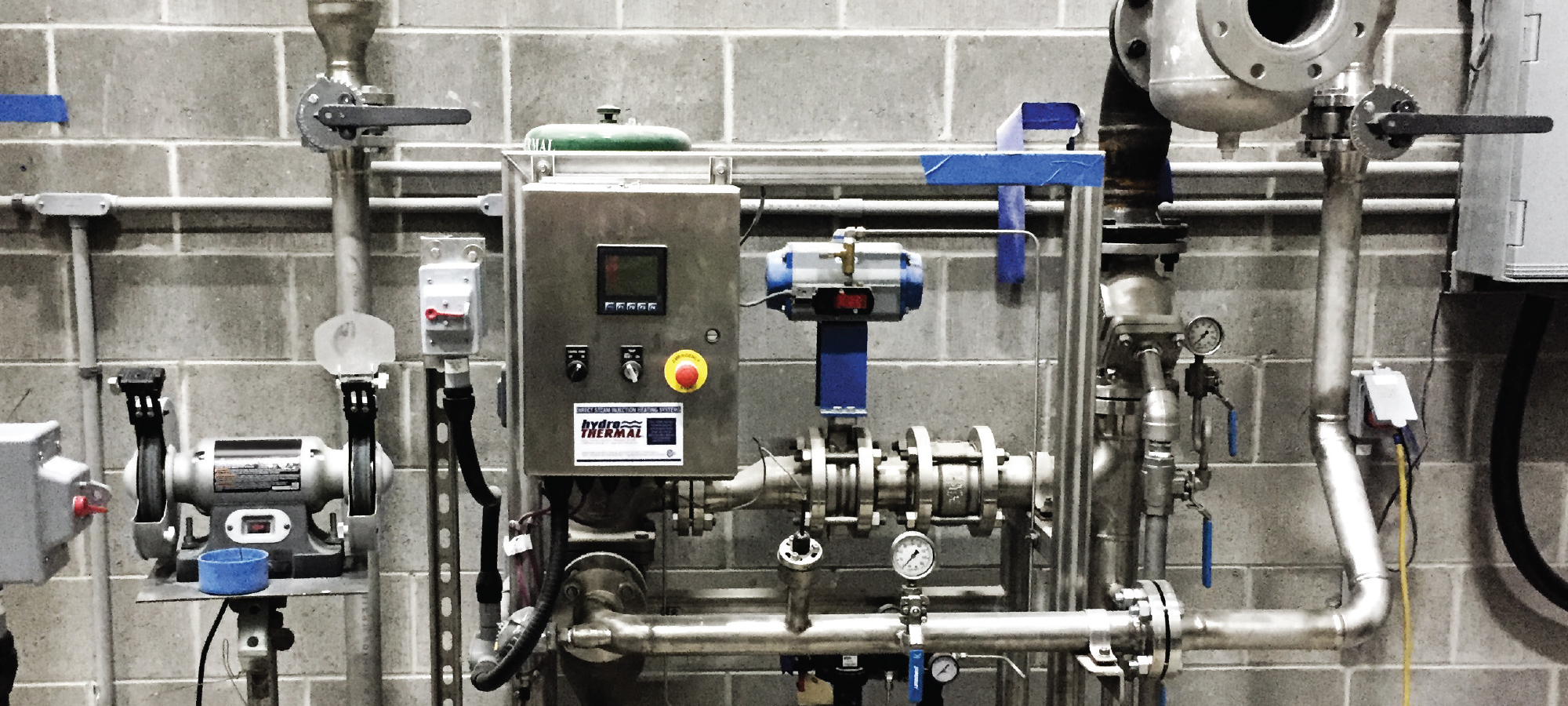

- Hydrothermal steam injection heaters

- PVI storage tanks

- Mixing valves

- Copper tube

- Plumbing fixtures and drainage

CHALLENGE

Provide technical support, design-build assistance, competitive pricing, and timely delivery of material to meet deadlines.

SOLUTION

Our design-build experts acquire, ship, and deliver pipe and stainless steel fittings at a competitive price, utilizing multiple internal resources, distribution centers, and branches around the country.

Our Advantage As Design-Build Experts

- Ability to leverage national resources to be competitive

- Availability of product through our distribution centers

- Offering technical expertise during the design phase

BACKGROUND

Clemens Food Group, a hog farming, food production, logistical services, and transportation company, hired Grey Construction to design and build Clemens Food Group’s new 656,000 sq. ft. pork processing operation in Coldwater, Michigan. After choosing Goyette as their mechanical contractor, Ferguson Industrial was selected as the PVF supplier and quickly joined the team to provide products and technical support during construction planning.

The project was awarded in phases as the processing facility was designed. Goyette awarded Ferguson Industrial the project based on our relationship, national footprint, product selection, service, and technical expertise for the design phase. “I feel that logistically, we are the only company in Michigan that could have supplied all of this material for this project mainly due to our distribution centers and product offerings,” said Lee Johnson, Area Sales Manager.

Utilizing our expansive nationwide resources, from collaborating with Ferguson Industrial design-build experts and associates across the country to our distribution centers and partners, we were able to secure pipe and stainless steel fittings from around the country quickly and efficiently while staying competitively priced.

Due to our success on this project as collaborators and partners, we are partnering on future projects with Goyette Mechanical and Grey Construction.

View Similiar Case Studies

Our Automated Supply Program (ASP)—an advanced, indirect material supply chain software—and our proven processes to control their MRO indirect spending reduced the total cost of ownership by 24.2% in the first year post-integration.

Our associates identified an opportunity to use our online Automated Valve Configuration Tool to build out exactly what the customer needed. In less than 15 minutes, our flow control experts were able to walk the customer through the process of configuring an FNW® automated ball valve package.

Expert technical assessment, material selection, and supply of Polypropylene at a quartz processing facility in North Carolina.