Complex Problems. Collaborative Solutions.

Our customers rely on our technical expertise from kickoff to completion.

For our customers, “Trust Earned Through Performance” is more than just a company tagline—it’s a realistic depiction of the relationship we share with all our valued customers and partners. We achieve strong partnerships through a progressive scope of expectations and consistent follow-through.

Recently, we collaborated with one of our customers—a biopharmaceutical company—and their engineering contractor. Together we worked to develop and implement a still in a water-for-injection plant. Thanks to our associates’ expertise, we offered solutions that would’ve otherwise been beyond one manufacturer’s capabilities. As a result, our team earned the respect of the client, contractor, and construction manager.

Furthermore, as the project progressed, the customer discovered another issue. In fact, an existing globe-style control valve was unable to isolate enough in order to keep the over-temperature alarm from going off. Consequently, it caused the system to shut down and prevented the still from filling.

Control Valve Repair

The customer turned to our team to repair the control valve because of our thoughtful, collaborative approach throughout the life of our partnership.

We recommended a Trimteck® control valve which is capable of ANSI Class V shutoff. Because the new valve assembly was isolated, it held the “Set Point Achieved” condition which in return fixed the over-temperature trigger. In addition, the valve required no additional I/O or programming to add an action to the control loop. The customer is now able to isolate and control with existing PID Loop and HMI buttons.

The valve assembly is now reliable, and the solution required minimal downtime for the plant. Not to mention, our customer now has the reassurance that they can always turn to us to provide timely solutions to complex challenges.

View Similiar Case Studies

Our Automated Supply Program (ASP)—an advanced, indirect material supply chain software—and our proven processes to control their MRO indirect spending reduced the total cost of ownership by 24.2% in the first year post-integration.

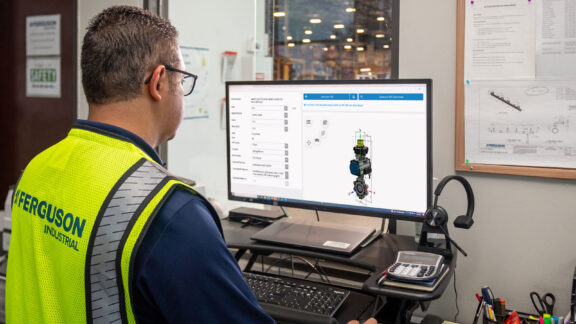

Our associates identified an opportunity to use our online Automated Valve Configuration Tool to build out exactly what the customer needed. In less than 15 minutes, our flow control experts were able to walk the customer through the process of configuring an FNW® automated ball valve package.

Expert technical assessment, material selection, and supply of Polypropylene at a quartz processing facility in North Carolina.