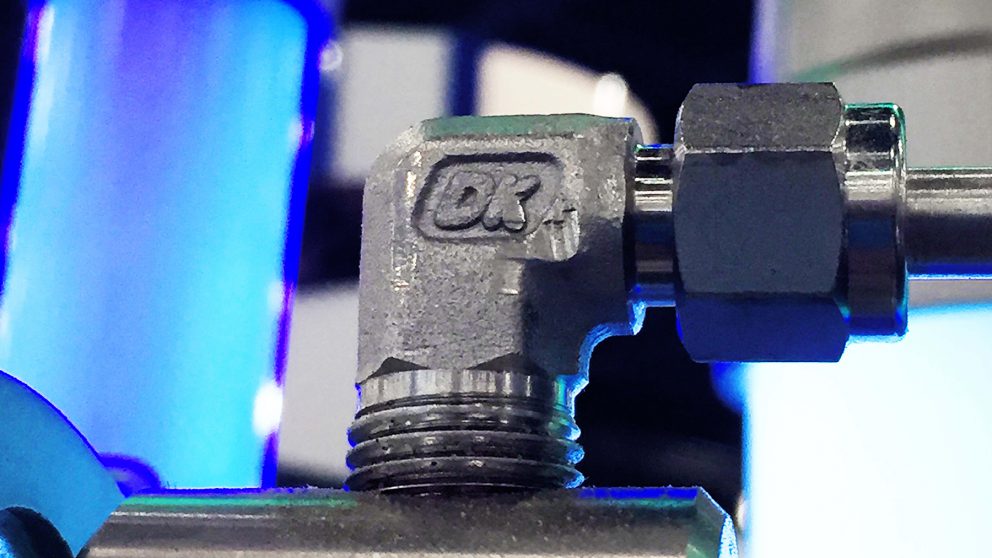

Your trusted source for DK-LOK® fittings and valves. Engineered for reliable performance in the most demanding industrial applications.

Your bottom line depends on predictability and performance

With all DK-Lok Fittings & Valves, we create solutions by reducing development cycles by introducing new and customized products to fit the customer’s specific needs through trust and close cooperation. We’re dedicated to the production and supply of the highest quality instrumentation tube fittings, valves, metallic flexible hoses and manifolds.

Quality consciousness and customer orientation are our basic principles and we provide customer satisfaction through continuous quality improvement and cost effective methods.

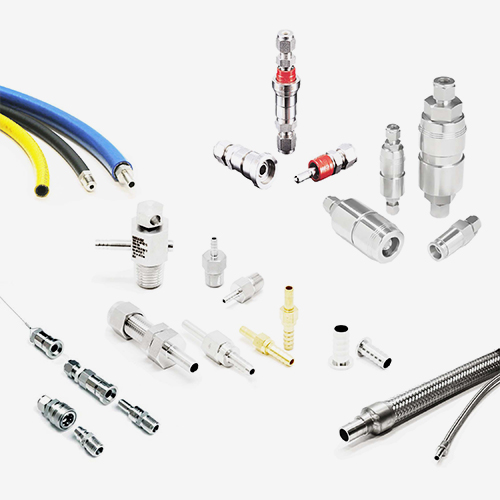

Fittings

- Manufactured Standard in dual grade SS 316L/316, Brass and Carbon Steel.

- Manufactured in Hastelloy, Monel™, Super Duplex, Duples, Alloy 20, Titanium and Teflon™.

- Instrumentation-Grade Pipe fittings available up to 2”.

- JIC Fittings – 37° flare fittings manufactured to SAE J514 specifications.

- Single Ferrule fittings manufactured in sizes 1/8” – 1-1/4”.

- The DK-LOK® two ferrule fitting delivers leak free performance as a PURE product but also if intermixed in ANY combination with Swagelok.

Valves

- Every valve is factory tested with nitrogen gas at 1000 psig for leakage at seat to a maximum allowable leak rate of 0.1 SCCM.

- Hard chrome-plated stem threads on our needle valves assures extended service life with metal to metal vee and regulated stems for elevated pressures.

- Inline check valves with fixed and adjustable cracking pressure settings.

- Relief valves with wide media applications – air, gas, CNG, and liquid relief applications.

UHP (Ultra High Purity)

- High Purity of a metal-to-metal seal and leak-tight service from vacuum to positive pressure.

- All adapters are manufactured, cleaned and packaged to meet the highest standards of cleanliness, surface finish level and material compatibility.

- Ultra-sonic cleaning performed in a class 100 environment.

- Products are double-bagged in a clean room using anti-static polyethylene bags with high purity nitrogen inclusion.

- Microfit and standard weld fittings available in multiple configurations.

Hose Products

- Serrated barbs on Hose Connectors, create leak tight seal.

- Push on hose fittings to configure assemblies in the field quickly and efficiently.

- High pressure and general purpose hose.

- Complete line of hose and fittings for industrial and hydraulic applications.

- Transfer chemicals, petroleum, air, or water.

- Quick connects with bi-directional flow design, SS316 construction with standard FKM O-Ring.

Call 1-503-683-8284 to speak with a DK-LOK® fittings and valves specialist today.

DK-LOK® fittings and valves are manufactured to the most stringent industry standards.

QUALITY

DK-LOK® products are held to a high standard of quality that conforms to specified requirements.

DIVERSIFICATION

DK-LOK® offers a diverse portfolio of valve and fitting products to meet a wide range of applications and needs.

CONSISTENCY

DK-LOK® is proud to offer an extensive selection of safe and reliable products that customers around the world count on each and every day.

TRUST

For five decades, DK-LOK® has provided customers like yourself with dependable products. Every product we create is done so with the trust of our customers in mind.

S.T.A.M.P.E.D

Size:

- What size End Connections?

- What is the Orifice Size? (Flow Determination)

Temperature:

- What is the System Media Temperature?

Application:

- What is the System Media of the Application?

- What is the External Environment of the Application?

Material:

- What is the Material Requirements of the Valve?

- Any specific or known requirements related to Material and Valve Body, Elastomers, and or Polymers?

Pressure:

- What is the Maximum System Working Pressure?

Ends:

- What “TYPE” of End Connections are Required?

Delivery:

- When does the customer need this item (qty’s) by?

- What are the delivery expectations of the customer?

- If we are unable to fully meet the lead times required by the customer, ask them if they are open to potential in-stock options that may have a different handle or seal material, etc. — but still cover the requirements laid out through this series of questions? Can they accept partial delivery as a way to secure their business?

Customer Case Study

Customer: Natgasoline Beaumont Tx

What was the customer’s issue?

Area of the plant was down

What products did we sell?

DUR-16-8-S (Tube Fittings)

How did this project highlight/utilize our technical expertise?

DK-LOK® had the parts on the shelf needed that Parker and Swagelok didn’t.

What benefits did the customer realize from working with Ferguson Industrial and our response?

- Reduced Lead Time

- Reduced Downtime

- Supplier responsive and reliable

- It was the weekend and DK-LOK® was able to make this happen on short notice, after hours

Resources

Connect With An Expert

Call 1-503-683-8284 or complete this form to discuss your project with a product expert.

Whether you are looking for specific products, need to discuss your comprehensive project, or are interested in our learning more about our packages, we are here to help.