Strategic Solutions.

Not only do we customize actuators and valves, but we develop strategic flow control solutions. Whether you’re troubleshooting a problem or retrofitting parts, rely on our team of experts because they approach every project with experience and precision. Furthermore, our custom fabrication and machining facilities are strategically located to serve you better.

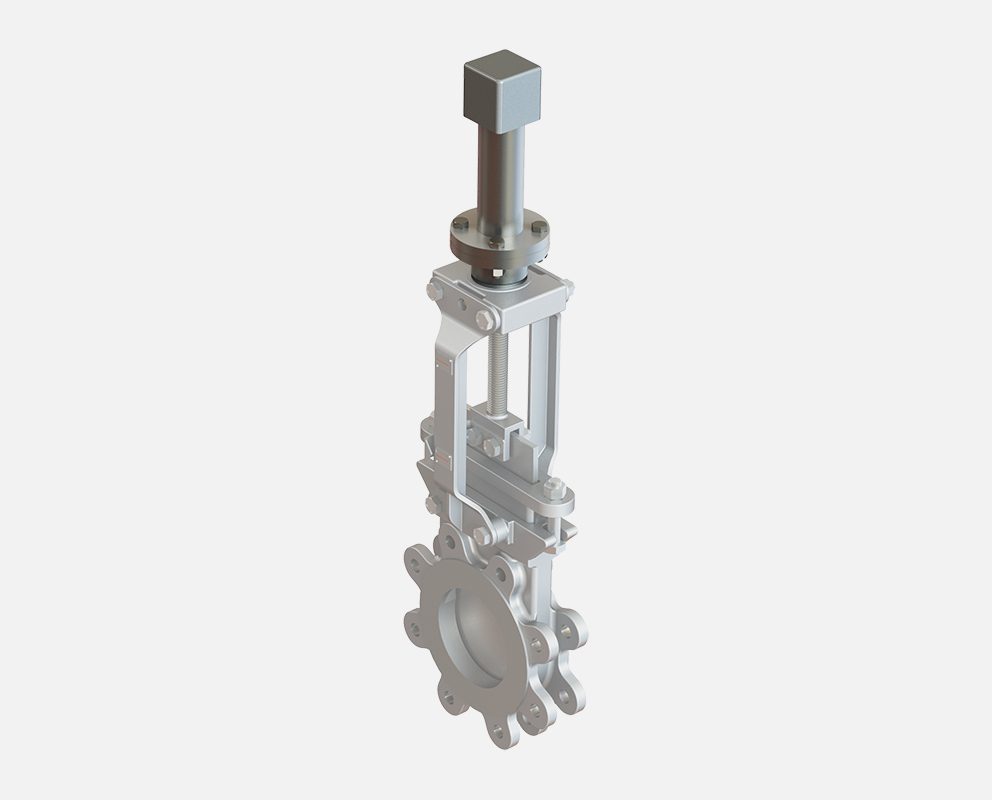

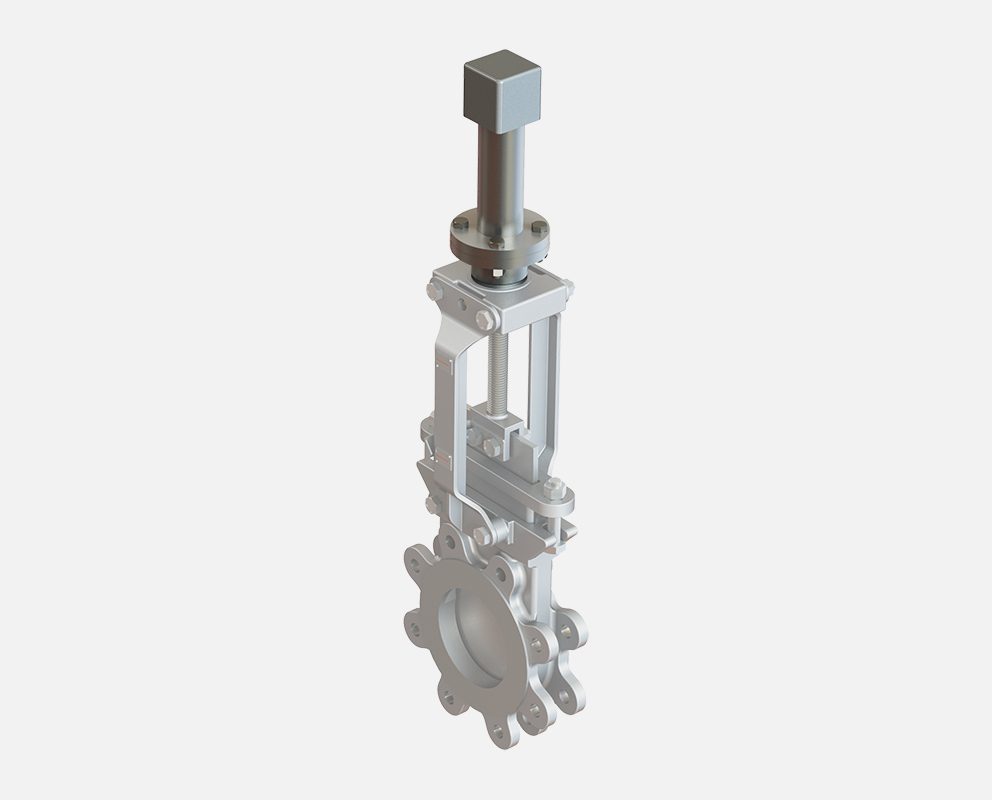

Actuator Mounting Hardware

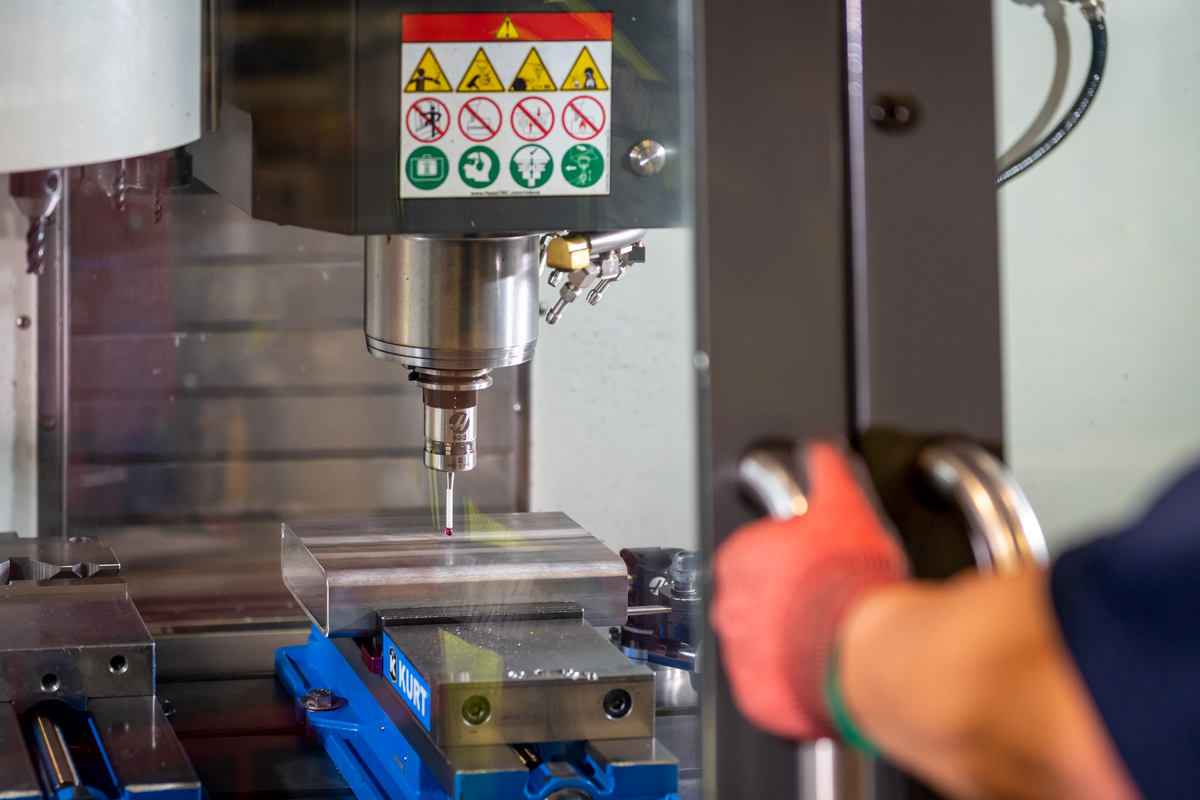

There are many valve manufacturers that only produce valves. In comparison, there are also manufacturers that only make actuators. We connect the two so that our customers can get fast, reliable solutions. At our strategically located service centers, we automate existing manual valves with proper actuators. We can also fabricate new parts to ensure seamless connections or meet application-specific requirements. This is typically done with fabricated mounting kits. Couplings are included in the kits to mate the valve stem to the actuator drive. In addition, we manufacture bushings to mate rotary or linear valves to electric actuators. Lastly, for applications that do not have a mounting pad, we machine custom plates. Our machinists, technicians, and investments in CNC equipment offer robust solutions that provide peace of mind. Let us know how we can help.

Stem Extensions

If accessing and operating valves is difficult and, consequently, unsafe for plant personnel, then our experts can design and install Stem Extensions. As a result, operations will be more convenient and safe. In addition, we can add gear operators or actuators to the top of the extension to reduce incidents. Connect with a Ferguson Industrial expert today to design a custom flow control solution.

Square Drive Nuts

Because some valves are in buried service, they may require a fabricated Square Drive Nut for proper operation. To address this problem, our company manufactures Square Drive Nuts for both linear and rotary valves. Ferguson Industrial is your comprehensive partner for premium flow control solutions and products.

Stem Nut Machining

For a smooth operating system, stem nut machining is important. In fact, stem nuts are the most common reason for failures in motor-operated valves. They may seem insignificant, however, as the drive element between the valve and the actuator, they are responsible for opening and closing valves. Consequently, Ferguson Industrial can machine threads for any size actuator in our machine shop. Furthermore, because we maintain a large inventory, our turnaround is fast. As a bonus, we do it at a fraction of the cost of OEMs.

Our Stem Nut Machining services include, but are not limited to:

- Threads for single, double, and triple lead threads

- 29-degree standard acme threads

- Stub acme threads

- Metric threads

- Internal threads for stems that have rolled threads

- Modified stub acme threads

- Bore and key steel stem nuts

- New yoke nuts for manually operated valves

- Wire EDM splines in nuts on the OD and ID for any configuration