HDPE Barge for Lake Oswego Corporation

In Need of Custom Floating Structures for Oswego Lake, The Lake Oswego Corporation Partnered with Ferguson Industrial for a Solution.

Lake Oswego Corporation chose Ferguson Industrial for technical support and specialized solutions during planning. As their HDPE supplier, we provided products to complete the project as well as an HDPE barge.

Industry:

Freshwater Recreation

Products:

Work barge with sealed compartments located in the floatation chambers to contain the algae control products.

Challenge:

Lake Oswego Corporation needed a vessel that could serve as a work barge for lake maintenance and hold the products used to control algae in the lake. The vessel also needed to have areas that would hold the products and tools used for their maintenance.

Solution:

Ferguson Industrial offered a work HDPE barge with sealed compartments located in the flotation chambers to contain the algae control products.

Advantages:

The finished product will not corrode or rust and does not promote microbial growth. Additional benefits include:

- Low lifetime cost

- Little to no maintenance

required - Environmentally friendly

- Durable onsite during construction

Overview

In recent years, Lake Oswego has suffered from summertime algae blooms due to fertilizer runoff from nearby properties. To help control the blooms, and for additional general lake maintenance, Lake Oswego Corporation manager Gabe Winfrey contacted Ferguson Industrial for assistance.

The Ferguson Industrial Industrial Plastics Division worked with Winfrey to design a custom 12′ x 32′ floating barge that could serve as a platform for workers to use to control algae blooms.

Ferguson Industrial manufactured a barge using HDPE (high-density polyethylene) materials and a galvanized steel frame. The newly fabricated 384-square-foot barge can carry up to 39,000 pounds of material, providing Lake Oswego Corporation with a durable, low-cost cost, and environmentally friendly barge that is expected to provide many years of service.

Because the lake already suffers from algae blooms, it was important to utilize materials that would not leach harmful contaminants into the lake water. HDPE and galvanized steel were the only logical choices, providing long service life while resisting rust, corrosion, and microbial growth.

About Lake Oswego Corporation

The Lake Oswego Corporation is an organization that manages and maintains the 415-acre Oswego Lake and its lakefront properties. The business is also responsible for the safety, water quality, maintenance, licensing, permitting, and special events in the area.

As a founding member of the Oswego Lake Watershed Council, they are a non-regulatory stewardship organization established to improve the conditions and health of the Oswego Lake watershed and its stream network.

View Similiar Case Studies

Our Automated Supply Program (ASP)—an advanced, indirect material supply chain software—and our proven processes to control their MRO indirect spending reduced the total cost of ownership by 24.2% in the first year post-integration.

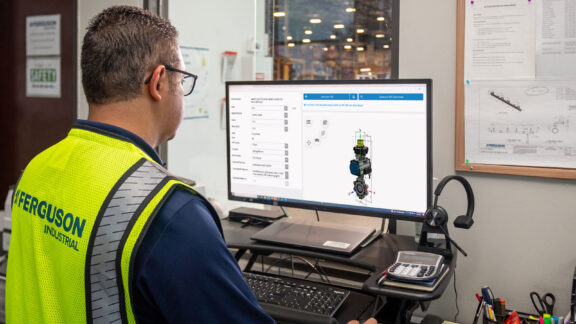

Our associates identified an opportunity to use our online Automated Valve Configuration Tool to build out exactly what the customer needed. In less than 15 minutes, our flow control experts were able to walk the customer through the process of configuring an FNW® automated ball valve package.

Expert technical assessment, material selection, and supply of Polypropylene at a quartz processing facility in North Carolina.