Restoring District Energy Through Online Automated Valve Configuration

Customer avoided a full plant outage that would have affected 30+ end users.

Download Restoring District Energy Through Online Automated Valve Configuration

PRODUCTS USED:

- Automated Valve Configurator Tool

- 1″ FNW® X440 Threaded Ball Valve

- FNW AC52SR11V Pneumatic Actuator

CHALLENGE:

A failed valve cut crucial access to dried air and chilled water access for a busy section of Oklahoma City’s business district.

SOLUTION:

A ready-in-minutes valve configuration, paired with in-stock products from an approved manufacturer.

KEY RESULT:

Customer avoided a full plant outage that would have affected 30+ end users.

PRODUCT ADVANTAGES:

- Expert associates with deep knowledge of product specifications and industry requirements

- Extensive inventory of automated valve products from trusted vendors

- Free online Automated Valve Configuration Tool

- Robust valve automation capabilities supported by a national footprint

PROJECT SUMMARY

BACKGROUND:

Beneath the streets of Oklahoma City, an extensive piping network distributes 99.9% reliable steam, hot water, and chilled water to customers in the Central Business District. More than 30 premier institutions and businesses—including the new Oklahoma City Convention Center—rely on this network for space heating and cooling, domestic hot and chilled water, humidification, and sterilization. This system, known as district energy, is an innovative and resilient energy solution that involves the production of thermal energy at a central plant. As a result, there is no need to install or manage onsite boilers and chillers.

CHALLENGE:

At the central plant, automated valves allow the system to switch back and forth between water and dried air. However, in one of these valves, regular wear and tear resulted in a failed actuator. Without a bypass for a quick workaround, the whole plant could have suffered an outage, disrupting service for all 30+ end users.

SOLUTION:

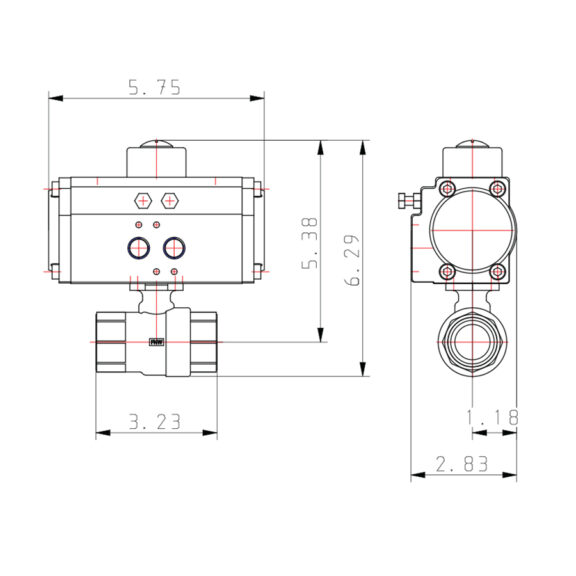

The customer contacted the Oklahoma City Ferguson Industrial location to source a replacement because the valve’s specifications required a customized solution. Our associates identified an opportunity to use our online Automated Valve Configurator in order to build out exactly what the customer needed. In less than 15 minutes, our flow control experts were able to walk the customer through the process of configuring an FNW® automated ball valve package. The Configurator generated specification documents and drawings for immediate review and approval.

Since FNW is an Approved Manufacturer and a national leader in valve actuation and modification, our locations keep FNW products on hand. That means we help reduce lead times on automated valve packages. Our team of experienced technicians uses drawings and specifications from the Automated Valve Configurator to automate the customized package using in-stock products. Then, they quickly ship the parts within a condensed timeline in order to get the plant back to optimal operation, ASAP

THE FERGUSON INDUSTRIAL DIFFERENCE

The customer knew they could trust us to provide an expedited replacement with expert service in this crucial moment because of our existing Vendor Managed Inventory relationship. In fact, associates from the Oklahoma City location visit this plant weekly to coordinate inventory and provide replenishment services. Due to our accessibility and familiarity with the industry, the plant’s operations, and the urgency of the application we were the first choice for partnership on this project.

View Similiar Case Studies

Our Automated Supply Program (ASP)—an advanced, indirect material supply chain software—and our proven processes to control their MRO indirect spending reduced the total cost of ownership by 24.2% in the first year post-integration.

Expert technical assessment, material selection, and supply of Polypropylene at a quartz processing facility in North Carolina.

Providing a North Carolina quartz processing plant with contaminant-free air with a lifecycle many times greater than steel pipe—ultimately saving the plant thousands in maintenance, repair, and replacement costs.